Cultivation process demands precision, dedication, and expertise at every stage of growth and development. The final steps in preservation make all the difference between ordinary results and exceptional quality. Professional cultivators who grow

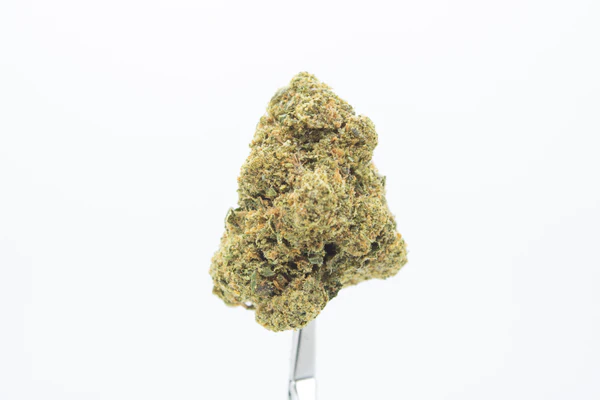

THCA flowers recognize that proper curing techniques directly impact the final product’s characteristics. The careful management of temperature, humidity, and time creates ideal conditions for preserving trichomes and maintaining potency.

Essential curing fundamentals

Curing process begins immediately after harvesting when moisture levels remain high within plant materials. During this critical phase, maintaining consistent environmental conditions prevents the degradation of valuable compounds while allowing beneficial metabolic processes to continue. This balance requires careful monitoring and adjustment throughout the entire curing duration.

- Temperature management for optimal results

Temperature control stands as one of the most crucial factors during curing. An environment between 60-70°F (15-21°C) proves ideal for preserving volatile compounds while preventing mould growth. Fluctuations outside this range compromise quality and potentially damage sensitive trichomes containing desired compounds.

- Humidity control techniques

Maintaining proper relative humidity levels between 55-65% during initial curing phases allows for gradual moisture release while preventing over-drying. As curing progresses, slight reductions in humidity help achieve optimal moisture content without compromising quality. Professional cultivators use calibrated hygrometers to monitor these levels continuously.

Advanced curing methods

- Air circulation principles

Proper air exchange removes excess moisture and prevents stagnant pockets where problems could develop. Gentle air movement, rather than direct fans, provides ideal circulation without causing physical damage to delicate trichomes. This careful balance maintains quality while managing moisture levels effectively.

- Container selection importance

The choice of curing containers impacts results significantly. Glass containers with airtight seals preserve volatile compounds effectively while allowing periodic air exchange during burping. Container size should match batch quantities, minimizing excess air space while providing adequate room for proper circulation.

- Duration and timing considerations

Initial curing typically spans 2-4 weeks, though some cultivators extend this period for enhanced results. Regular monitoring determines when materials reach peak quality, as environmental factors influence optimal duration. Patient attention to detail during this period yields superior outcomes.

The first week proves most critical, requiring daily inspection and container burping to release accumulated gases and moisture. As curing progresses, these intervals extend while maintaining careful observation of conditions and development.

Quality indicators throughout the process

Several factors indicate proper curing progression:

- Gradual colour deepening without fading

- Development of complex aromatic profiles

- Texture improvements without brittleness

- Even moisture distribution throughout materials

Storage after curing completion

Once curing concludes, proper storage maintains quality achievements. Consistent temperatures around 65°F (18°C) and relative humidity near 58-62% preserve material integrity. Regular monitoring ensures conditions remain stable, protecting valuable compounds from degradation.

Professional cultivation standards

Expert cultivators maintain detailed records throughout the curing process, tracking environmental data and quality progression. This documentation helps refine techniques and achieve consistent results across different batches of THCA flowers while identifying optimal conditions for specific varieties.

The dedication to proper curing techniques directly influences THCA flower quality outcomes. Through careful attention to environmental factors, timing, and professional protocols, cultivators achieve exceptional results. This commitment to excellence throughout the curing process ensures preserved compounds and optimal characteristics in the final product.